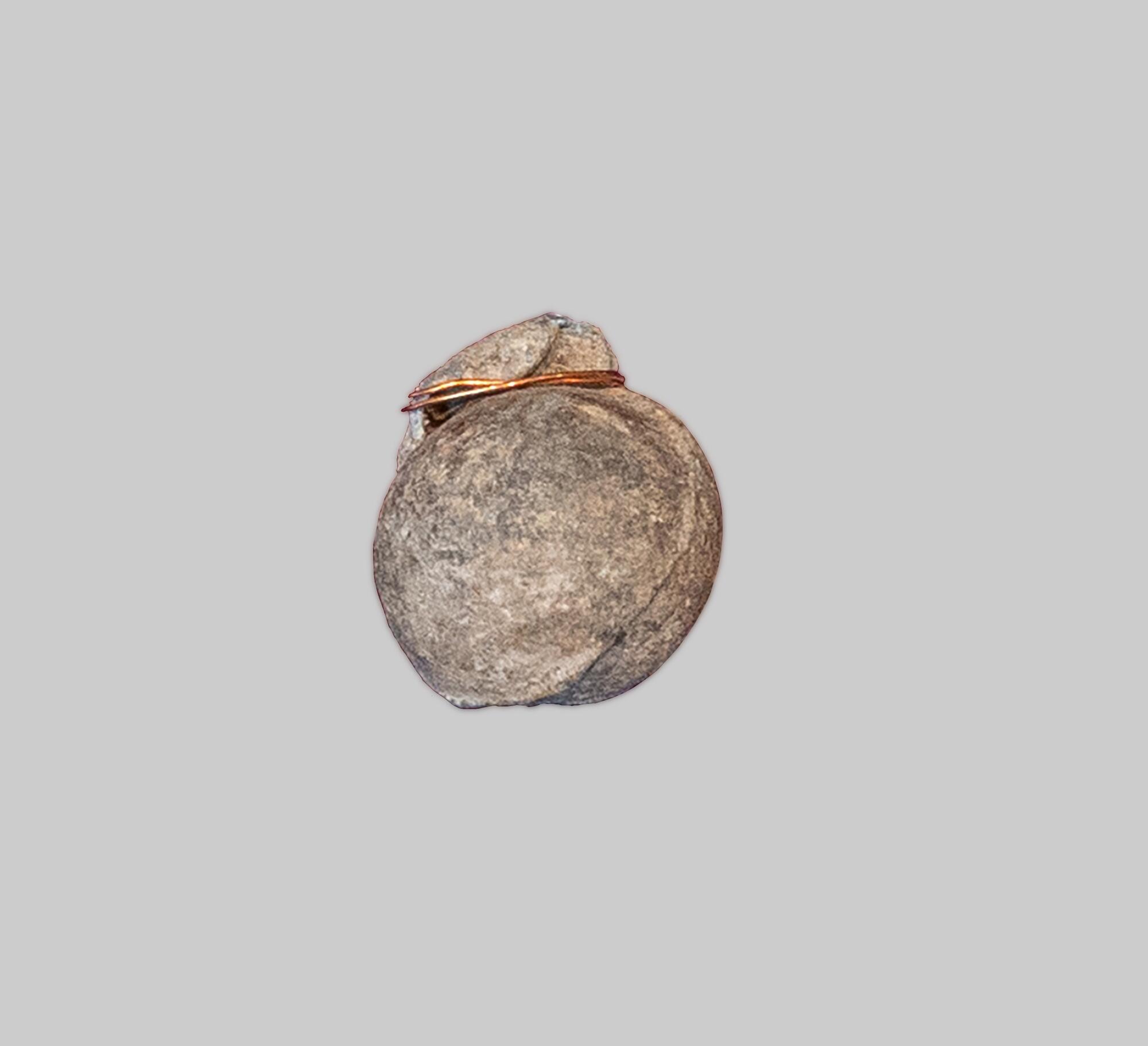

Out-of-shape roundish lead bullet with a remaining sprue was found during the excavation in Kuznetsk ostrOg. The bullet has a minor defect – its hemispheres were shifted a little relative to one another while casting. Such bullets were most often designed for firing from arquebuses.

An arquebuse is a muzzle-loaded flintlock gun. The first metal bullets were not always strictly ball-shaped, and their size could be smaller than the weapon caliber. It was deemed a permissible error. However, with the development of engineering and discoveries in the area of ballistics the quality of bullet manufacturing gradually improved.

Lead-cast bullets turned to be most efficient shells due to the specific weight of the metal. It was easier to give a ball shape to a lead bullet than to an iron one, besides, the lead bullets were heavy despite their small size. The bullets were cast by the weapon owners themselves, in special appliances – bullet molds (‘puleEika’). After casting the bullet there remained a sprue (‘tail’) on its surface.

There were two ways to fabricate ball-shaped lead bullets. The first method was to pour the melted lead into a special form of the size matching the barrel size. For a quality casting the form needed to be heated to a certain temperature, so the first batches of bullets that heated the form were taken out and then remelted, applying the adequate technology. The ready bullets were put on special woven felt for cooling, and then the sprue was cut.

In the second case the melted lead was poured into water or oil, through a sieve. The sieve meshes shaped the bullets of the required size while the water or oil cooled the lead to the necessary temperature.

Lead is one of the most common metals, it has been known since ancient times. Most widely industrially used alloy is that of lead and tin. The alloy of one part of lead and two parts of tin was used to connect the pipelines and electric wires. The jackets of telephone cables, certain batteries can also contain lead. Those metal alloys were also widely used in shipbuilding.

An arquebuse is a muzzle-loaded flintlock gun. The first metal bullets were not always strictly ball-shaped, and their size could be smaller than the weapon caliber. It was deemed a permissible error. However, with the development of engineering and discoveries in the area of ballistics the quality of bullet manufacturing gradually improved.

Lead-cast bullets turned to be most efficient shells due to the specific weight of the metal. It was easier to give a ball shape to a lead bullet than to an iron one, besides, the lead bullets were heavy despite their small size. The bullets were cast by the weapon owners themselves, in special appliances – bullet molds (‘puleEika’). After casting the bullet there remained a sprue (‘tail’) on its surface.

There were two ways to fabricate ball-shaped lead bullets. The first method was to pour the melted lead into a special form of the size matching the barrel size. For a quality casting the form needed to be heated to a certain temperature, so the first batches of bullets that heated the form were taken out and then remelted, applying the adequate technology. The ready bullets were put on special woven felt for cooling, and then the sprue was cut.

In the second case the melted lead was poured into water or oil, through a sieve. The sieve meshes shaped the bullets of the required size while the water or oil cooled the lead to the necessary temperature.

Lead is one of the most common metals, it has been known since ancient times. Most widely industrially used alloy is that of lead and tin. The alloy of one part of lead and two parts of tin was used to connect the pipelines and electric wires. The jackets of telephone cables, certain batteries can also contain lead. Those metal alloys were also widely used in shipbuilding.