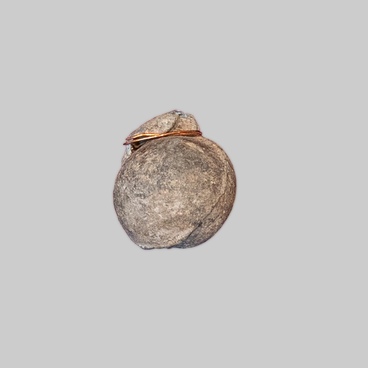

The bullet from the museum collection was found in excavations of Kuznetsk ostrog. It is designed for firing from a hand arquebuse – a hand flint-lock firearms. Service class people manufactured such bullets in special bullet molds. The bullets were made of the lead issued to them to do their military service.

Lead is a cheap easily melted material resistant to humidity fluctuations. That is why it has been used for casting bullets and shells since ancient times.

The firearms that entered service with the European armies in XIV century changed the battle tactics dramatically. Metal munitions were made primarily from lead as the material was very common, accessible and easily melted. As compared to iron, it was easier to give a ball shape to lead, and when striking the target the bullet lost its shape thus increasing the stopping power. Besides, despite the relatively small size, the lead bullets were sufficiently heavy and strong.

Several different techniques were applied to casting lead bullets in the Russian state of XVI–XVIII centuries. The principal method of giving the necessary ball-shape to the bullet was casting in bullet molds (‘pulelEika’). The melted lead was poured into a special form of the size matching the barrel size. Strict watch was kept for the bullet molds to maintain them dry, otherwise the melted lead could sprinkle as hot oil on the pan.

Several first batches heated the form to a set temperature, the lead used for that purpose was then remelted. The cast bullets were put on a felt or woolen cloth. After that, the sprue, or ‘tail’ remaining on the bullet surface was cut away.

The second method involved pouring melted lead into water or oil, through a sieve, instead of casting it in special molds. The sieve meshes shaped the bullets of the required size, in the flight the lead acquired the ball shape and cooled in the liquid.

That method was primarily used for manufacturing bird shot, but the archaeological discoveries allow to state that it was also used for bullets fabrication.

For commercial manufacturing of bullets, special high shot towers were built. In handicraft workshops the lead was poured into a specially dug well or into a barrel filled in with liquid, or the melted metal was poured through a sieve over an inclined surface covered by a fabric. The disadvantage of such method was that if the time was not enough for the metal to get cool during the flight, the bullet or the bird shot came out uneven and resembled an ordinary non-processed piece of lead.

Lead is a cheap easily melted material resistant to humidity fluctuations. That is why it has been used for casting bullets and shells since ancient times.

The firearms that entered service with the European armies in XIV century changed the battle tactics dramatically. Metal munitions were made primarily from lead as the material was very common, accessible and easily melted. As compared to iron, it was easier to give a ball shape to lead, and when striking the target the bullet lost its shape thus increasing the stopping power. Besides, despite the relatively small size, the lead bullets were sufficiently heavy and strong.

Several different techniques were applied to casting lead bullets in the Russian state of XVI–XVIII centuries. The principal method of giving the necessary ball-shape to the bullet was casting in bullet molds (‘pulelEika’). The melted lead was poured into a special form of the size matching the barrel size. Strict watch was kept for the bullet molds to maintain them dry, otherwise the melted lead could sprinkle as hot oil on the pan.

Several first batches heated the form to a set temperature, the lead used for that purpose was then remelted. The cast bullets were put on a felt or woolen cloth. After that, the sprue, or ‘tail’ remaining on the bullet surface was cut away.

The second method involved pouring melted lead into water or oil, through a sieve, instead of casting it in special molds. The sieve meshes shaped the bullets of the required size, in the flight the lead acquired the ball shape and cooled in the liquid.

That method was primarily used for manufacturing bird shot, but the archaeological discoveries allow to state that it was also used for bullets fabrication.

For commercial manufacturing of bullets, special high shot towers were built. In handicraft workshops the lead was poured into a specially dug well or into a barrel filled in with liquid, or the melted metal was poured through a sieve over an inclined surface covered by a fabric. The disadvantage of such method was that if the time was not enough for the metal to get cool during the flight, the bullet or the bird shot came out uneven and resembled an ordinary non-processed piece of lead.