Many crafts were developed in Volga Bulgaria, among them there is leather production and processing of animal bones. Historians and archaeologists have managed to reconstruct in general terms the technology of bone carving. At the first stage, masters selected raw materials that were best suited for the product. Then the Bulgarians prepared the material and began to carve. At the final stage, they polished and decorated the finished item. During the excavations, archaeologists found both blanks and already made samples.

Bone products were sold within the city and in the surrounding settlements. Researchers believe that Bulgar craftsmen could supply their products even outside of Volga Bulgaria.

Carvers also made their tools for working with leather. Items made of this material were in great demand — both in the West and in the East. Especially valuable was a unique sort of finely processed leather, the technology of which was known only to Bulgar craftsmen. The secret of leathercrafters is still unknown.

For ordinary items, leather was first soaked in water and thoroughly cleaned, then came softening and tanning. To soften the material, it was treated with enzymes, under the influence of which the remains of hair follicles and upper layers of leather were removed from the pores. During the tanning process, there were special substances used that made the leather stronger. In ancient times, leathercrafters knew only vegetable tanning agents such as tannin. Often it was obtained from the gall nuts that form on the leaves of the oak tree from infectious or parasitic diseases and the oak tree bark. After treatment with tannin, the skin was smoothed and oiled, that is, treated with fats so that it would not become rough and cracked.

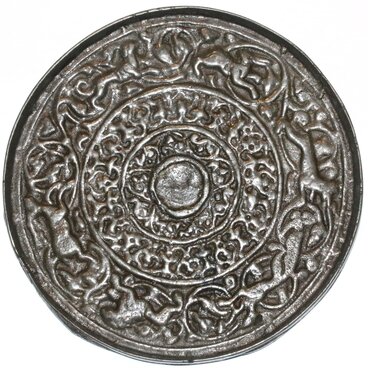

After the material passed all stages of processing, Bulgars proceeded to stamp leather. Beforehand leather could be slightly cut so that the pattern was laid better, but sometimes crafters worked without cutting. A special tool was used for stamping, which was made of a long bone. A deep diagonal grid was made on one of its sides, which served as a peculiar pattern.

Bone products were sold within the city and in the surrounding settlements. Researchers believe that Bulgar craftsmen could supply their products even outside of Volga Bulgaria.

Carvers also made their tools for working with leather. Items made of this material were in great demand — both in the West and in the East. Especially valuable was a unique sort of finely processed leather, the technology of which was known only to Bulgar craftsmen. The secret of leathercrafters is still unknown.

For ordinary items, leather was first soaked in water and thoroughly cleaned, then came softening and tanning. To soften the material, it was treated with enzymes, under the influence of which the remains of hair follicles and upper layers of leather were removed from the pores. During the tanning process, there were special substances used that made the leather stronger. In ancient times, leathercrafters knew only vegetable tanning agents such as tannin. Often it was obtained from the gall nuts that form on the leaves of the oak tree from infectious or parasitic diseases and the oak tree bark. After treatment with tannin, the skin was smoothed and oiled, that is, treated with fats so that it would not become rough and cracked.

After the material passed all stages of processing, Bulgars proceeded to stamp leather. Beforehand leather could be slightly cut so that the pattern was laid better, but sometimes crafters worked without cutting. A special tool was used for stamping, which was made of a long bone. A deep diagonal grid was made on one of its sides, which served as a peculiar pattern.