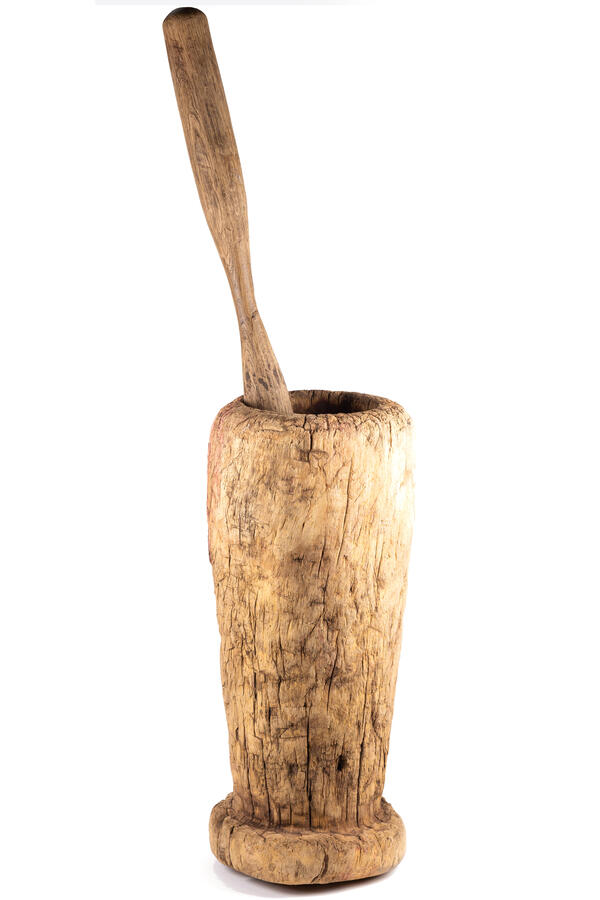

The mortar and pestle represent one of the oldest human tools used to grind grains and other food products. The mortar and pestle were used to make cereals from unrefined grains like wheat, barley, millet, and buckwheat, as well as for grinding salt. It is common knowledge that people used mortars and pestles as early as the 8th millennium BC. The mortar and pestle on display at the museum were made in the 19th century.

Usually, mortars were cut from an elongated stump of wood, and in most cases they took the shape of a large shot glass: the elongated upper part gradually narrowed downward, and rested on a round, thickened base. They could be up to 80 cm in height, 50 cm in depth, and 40 cm in diameter. The wooden pestle usually had a length reaching 100 cm, but rarely exceeded 7 cm in diameter. More often than not, the pestle and mortar were made from the same material. For effectively crushing particularly tough substances, they were filled up to no more than 5% of the mortar’s total volume.

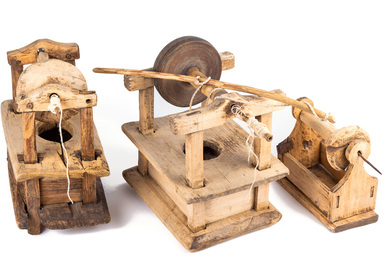

A mortar and pestle used to be in every peasant household. Most frequently, they were used to store up on cereals, and usually it was stocked up on for several weeks of future use all at once. Another invariable purpose of the mortar was to mash the soaked, dried stems of hemp and flax (although flax was more often crushed using a special device — a decorticator). As a result of crushing the plant fibers, the raw materials used in sewing and weaving were obtained: tow, tow fibers, and hemp fibers. There were also double mortars, with one end that was used for crushing millet and the other end for crushing flax. A mortar for was also used for washing and pounding canvas cloth.

The size, shape, and purpose of the pestle also varied depending on the properties of the item being processed (e.g. its hardness), and how it was supposed to be treated. There were pestles that existed with rounded and flat working surfaces. A rounded pestle is suitable for grinding hard plants and substances, while a flat pestle is only suitable for grinding relatively soft food products. In Russia, a wooden pestle with a flat working surface is also known as a “masher”. It was often used to crush boiled potatoes, berries, and other foods.

Usually, mortars were cut from an elongated stump of wood, and in most cases they took the shape of a large shot glass: the elongated upper part gradually narrowed downward, and rested on a round, thickened base. They could be up to 80 cm in height, 50 cm in depth, and 40 cm in diameter. The wooden pestle usually had a length reaching 100 cm, but rarely exceeded 7 cm in diameter. More often than not, the pestle and mortar were made from the same material. For effectively crushing particularly tough substances, they were filled up to no more than 5% of the mortar’s total volume.

A mortar and pestle used to be in every peasant household. Most frequently, they were used to store up on cereals, and usually it was stocked up on for several weeks of future use all at once. Another invariable purpose of the mortar was to mash the soaked, dried stems of hemp and flax (although flax was more often crushed using a special device — a decorticator). As a result of crushing the plant fibers, the raw materials used in sewing and weaving were obtained: tow, tow fibers, and hemp fibers. There were also double mortars, with one end that was used for crushing millet and the other end for crushing flax. A mortar for was also used for washing and pounding canvas cloth.

The size, shape, and purpose of the pestle also varied depending on the properties of the item being processed (e.g. its hardness), and how it was supposed to be treated. There were pestles that existed with rounded and flat working surfaces. A rounded pestle is suitable for grinding hard plants and substances, while a flat pestle is only suitable for grinding relatively soft food products. In Russia, a wooden pestle with a flat working surface is also known as a “masher”. It was often used to crush boiled potatoes, berries, and other foods.