The Zlatoust Ironworks, like all the plants in the Urals, was both a blast-furnace plant and an iron-making plant; in other words, the workers there not only smelted pig iron but also processed it into malleable bar iron. The plant was water-driven: water was the main source of energy, which is why the dam was considered the most important plant structure. It had conduits for the discharge of spring flood water, as well as a working conduit, through which water was supplied to the water wheels.

The plant consisted of individual factories or, in today’s terminology, workshops, which usually operated in a single production cycle. During the period when the Zlatoust plant began its operations, there were four hearths and the same number of hammers in its workshops. By 1820, at the Zlatoust plant, which by the time had become state-owned, there were already 24 blooming hearths with 24 blooming hammers.

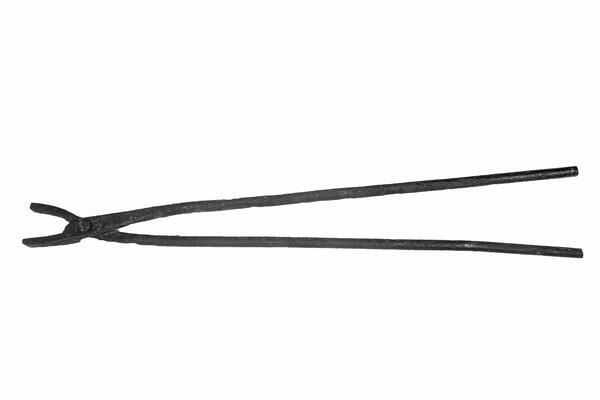

The bloom tongs (pincers) on display in the museum’s exhibition were made at an early stage, back in the 18th century; they were found during earthworks on the territory of the Zlatoust Ironworks in the early 1950s. Now it is known that they were made with artisanal techniques, by blacksmith forging.

The tongs have fairly long cylinder-shaped handles and flat jaws. Two symmetrical halves were interconnected with a massive rivet. The tongs were used to extract iron bloom from the blooming furnace.

The bloomery of pig iron was in essence stripping the iron of excessive amounts of carbon, silicon, and other impurities to obtain malleable metal. The iron was refined in blooming furnaces (hearths). The hearth was charged with pig iron and charcoal, the latter serving as a fuel.

Feeding the air to raise the temperature was carried out using bellows, set in motion through water-driven wheels. The pieces of bloom — porous lumps of softened iron, which were obtained as a result of the whole process — were saturated with slag and other inclusions. Once obtained, they were to be forged on bloom hammers, which were installed next to the hearths, to compact the bloom and remove undesirable inclusions.

The plant consisted of individual factories or, in today’s terminology, workshops, which usually operated in a single production cycle. During the period when the Zlatoust plant began its operations, there were four hearths and the same number of hammers in its workshops. By 1820, at the Zlatoust plant, which by the time had become state-owned, there were already 24 blooming hearths with 24 blooming hammers.

The bloom tongs (pincers) on display in the museum’s exhibition were made at an early stage, back in the 18th century; they were found during earthworks on the territory of the Zlatoust Ironworks in the early 1950s. Now it is known that they were made with artisanal techniques, by blacksmith forging.

The tongs have fairly long cylinder-shaped handles and flat jaws. Two symmetrical halves were interconnected with a massive rivet. The tongs were used to extract iron bloom from the blooming furnace.

The bloomery of pig iron was in essence stripping the iron of excessive amounts of carbon, silicon, and other impurities to obtain malleable metal. The iron was refined in blooming furnaces (hearths). The hearth was charged with pig iron and charcoal, the latter serving as a fuel.

Feeding the air to raise the temperature was carried out using bellows, set in motion through water-driven wheels. The pieces of bloom — porous lumps of softened iron, which were obtained as a result of the whole process — were saturated with slag and other inclusions. Once obtained, they were to be forged on bloom hammers, which were installed next to the hearths, to compact the bloom and remove undesirable inclusions.