A bathometer (the term used in Russian corresponds in function to a Nansen bottle in English) is a device for taking water samples at different depths. Its name comes from the two Greek words bathos and metron, which translate as “depth” and “measure”. This instrument is essential for any oceanographic expedition. It can be used to examine a water sample from great depths, to study its chemical composition, physical properties, and the content of inorganic impurities or organic particles.

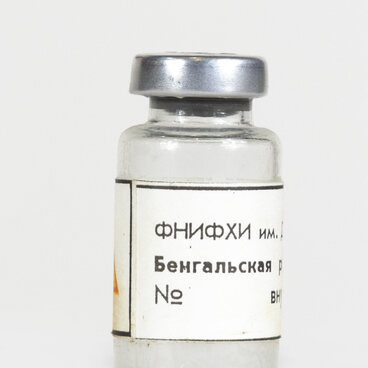

The first water samplers appeared 500 years ago. They looked like bottles and were only suitable for depths of no more than 50 meters. Modern devices are made in the form of a vessel with valves and caps designed to ensure that a sample of water can be taken at depth and kept from being contaminated during the ascent. Today there are seven main types of water sampling devices, among which are serial, bottom and depth ones. They are also classified according to the way they are filled with water: the flash-filled ones are closed immediately by means of a weight, while the long-filled ones are filled with water at the speed of the current.

The deep-water sampler from the collection of the Museum of the History of Obninsk was made at the Obninsk Central Design Bureau for Hydrometeorological Instrumentation. The engineers at the bureau specialize in devices for collecting and analyzing environmental parameters. Their range includes ground stations, devices for aircraft and instruments for research in water. The “Bathometer Probe”, the “Hydroprobe” and the “Mars Probe” measure oceanological parameters at depths of up to 6,000 meters.

The water sampler is also used to measure the temperature, pressure, conductivity and salinity of seas and oceans at depths of up to two kilometers. More than a dozen devices are submerged from a drifting ship for a single survey. At the base of the sampler is a cylindrical basket welded together from a thick metal rod coated in white enamel. This is a protective structure so that the device is not damaged by the impact on the side of the ship during ascent or descent.

The basket is also used as a support for the device while on the deck. On the bottom, bars in the center support the base, which consists of two overlapping metal washers. A fragment of the side wall of the casing of the lowering unit is covered with transparent plexiglass, through which the electronic units can be seen.

The first water samplers appeared 500 years ago. They looked like bottles and were only suitable for depths of no more than 50 meters. Modern devices are made in the form of a vessel with valves and caps designed to ensure that a sample of water can be taken at depth and kept from being contaminated during the ascent. Today there are seven main types of water sampling devices, among which are serial, bottom and depth ones. They are also classified according to the way they are filled with water: the flash-filled ones are closed immediately by means of a weight, while the long-filled ones are filled with water at the speed of the current.

The deep-water sampler from the collection of the Museum of the History of Obninsk was made at the Obninsk Central Design Bureau for Hydrometeorological Instrumentation. The engineers at the bureau specialize in devices for collecting and analyzing environmental parameters. Their range includes ground stations, devices for aircraft and instruments for research in water. The “Bathometer Probe”, the “Hydroprobe” and the “Mars Probe” measure oceanological parameters at depths of up to 6,000 meters.

The water sampler is also used to measure the temperature, pressure, conductivity and salinity of seas and oceans at depths of up to two kilometers. More than a dozen devices are submerged from a drifting ship for a single survey. At the base of the sampler is a cylindrical basket welded together from a thick metal rod coated in white enamel. This is a protective structure so that the device is not damaged by the impact on the side of the ship during ascent or descent.

The basket is also used as a support for the device while on the deck. On the bottom, bars in the center support the base, which consists of two overlapping metal washers. A fragment of the side wall of the casing of the lowering unit is covered with transparent plexiglass, through which the electronic units can be seen.