If you hit a surface with an ordinary hammer, it’s bound to bounce off, at least a little bit. This happens according to the law of momentum preservation: as a result of an elastic impact, the hammer starts to move in the opposite direction with the same impulse.

This effect is particularly pronounced in space, where the instrument itself, as well as the astronaut using it, will be thrown away after hitting a surface with a simple hammer. Such a “unmanageable” hammer can damage the surface of a space station and injure the astronaut.

So to work in zero gravity outside the spaceship, scientists developed a special, nonreactive hammer. It is also known as an dead-blow, recoilless, or space hammer. Its main property is lack of recoil.

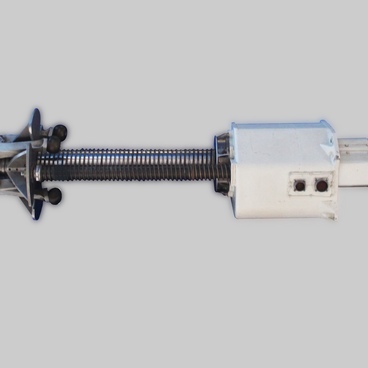

This hammer has a special design - a special arrangement of the component parts. Its long, corrugated handle is provided with a fastening element for a strong twine, and the rectangular hollow head is filled with loose contents. Usually, metal balls, lead pellets. At the moment of impact, the balls at the bottom of the head move upwards and the top balls move downwards. The friction between them dissipates the recoil energy, and the space hammer doesn’t recoil from the impact.

Space hammers are made of high-alloy (containing many special elements) corrosion-resistant steel.

Such hammers are also used on Earth. Typically, they are used for precise repairs, during which the adjacent parts or surfaces cannot be damaged. For example, during the repair of a car they are used to work with wheels, displace stuck parts, remove dents on the body. Such tools make it possible to control the impact force during engine or gearbox repairs.

Dead-blow hammers are also useful for the maintenance of hydraulic machines. They’re used to release the stuck cylinders without damaging their precision surfaces.

In metalworking, such hammers are used to ensure the correct contact of the work pieces to parallels of the machine tool clamps. And in telecommunications, they are used to make large-diameter cables inside cable passages.

This effect is particularly pronounced in space, where the instrument itself, as well as the astronaut using it, will be thrown away after hitting a surface with a simple hammer. Such a “unmanageable” hammer can damage the surface of a space station and injure the astronaut.

So to work in zero gravity outside the spaceship, scientists developed a special, nonreactive hammer. It is also known as an dead-blow, recoilless, or space hammer. Its main property is lack of recoil.

This hammer has a special design - a special arrangement of the component parts. Its long, corrugated handle is provided with a fastening element for a strong twine, and the rectangular hollow head is filled with loose contents. Usually, metal balls, lead pellets. At the moment of impact, the balls at the bottom of the head move upwards and the top balls move downwards. The friction between them dissipates the recoil energy, and the space hammer doesn’t recoil from the impact.

Space hammers are made of high-alloy (containing many special elements) corrosion-resistant steel.

Such hammers are also used on Earth. Typically, they are used for precise repairs, during which the adjacent parts or surfaces cannot be damaged. For example, during the repair of a car they are used to work with wheels, displace stuck parts, remove dents on the body. Such tools make it possible to control the impact force during engine or gearbox repairs.

Dead-blow hammers are also useful for the maintenance of hydraulic machines. They’re used to release the stuck cylinders without damaging their precision surfaces.

In metalworking, such hammers are used to ensure the correct contact of the work pieces to parallels of the machine tool clamps. And in telecommunications, they are used to make large-diameter cables inside cable passages.