The machine-building operations moved to Bashkortostan during WWII were integrated with the local industries. The Lenin Machine Factory from Odessa was set up at the site of the Sterlitamak mechanical tractor station. The Oil Industry Ministry’s machine-building operations from Tuapse were integrated with the Blagoveshensk plants.

Dedicated engineers and workers quickly managed to set up the largest machine-building operations in the Soviet Union. It took just a few months to assemble and commission operations for the production of low voltage equipment and machine assembly, and to launch the construction of three drilling equipment plants.

The Ufa Motor Plant (ODK – Ufa Motor-Building Association today) that used to produce harvester engines, became the site for aircraft-building enterprises from Rybinsk, Moscow and Leningrad. The construction of the plant began ten years before the war, and only four years later it produced its first engines for agricultural vehicles. In 1940, the plant was expected to reach full capacity, but was instead transferred to the ministry responsible for aircraft-building in the Soviet Union.

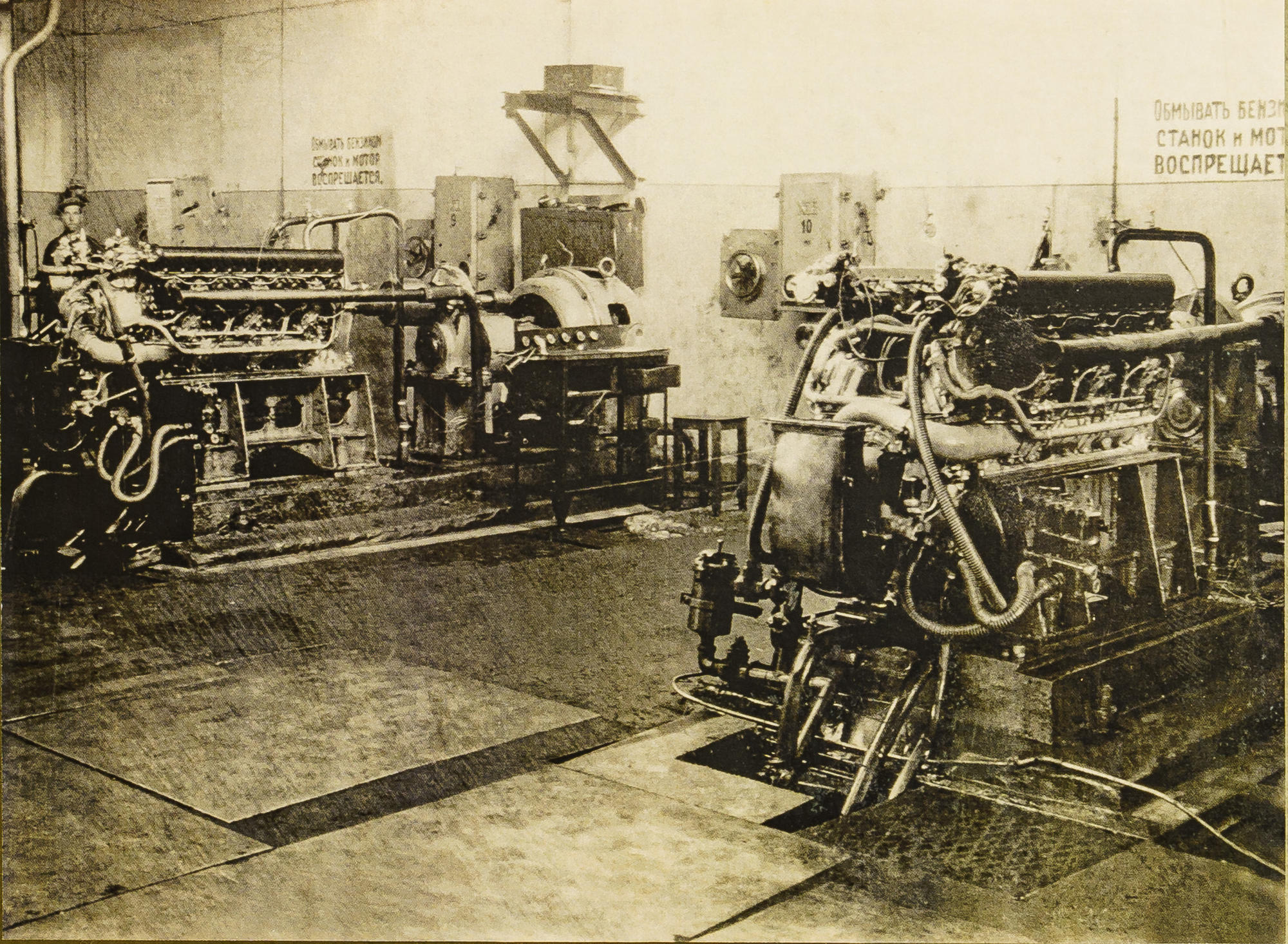

In wartime the Ufa Motor Plant manufactured the Klimov-design M-13 and VK-105 aircraft engines, producing 50-60 units a day. Over the four years of the war the plant manufactured over 5,000 aircraft engines. Its engineers and workers produced engines for Pe-2 bombers and Yak-3, Yak-7 and Yak-9 fighter aircraft.

The aircraft-building equipment at the Ufa Motor Plant had to be installed during the coldest winter months of 1941 – 1942. But despite the severe cold the workers constructed 11 production shops, laid down 42 km of railways and built a depot and transport facilities. The strategically important construction project employed 6,600 people who were accommodated in the 127 newly erected buildings and barrack houses and at two camp sites.

The important role played by the Ufa Motor Plant in the war effort can hardly be overestimated: every third aircraft carried the engine it produced, and the Yak-9U running an Ufa motor was pronounced the fastest WWII aircraft fighter.

Dedicated engineers and workers quickly managed to set up the largest machine-building operations in the Soviet Union. It took just a few months to assemble and commission operations for the production of low voltage equipment and machine assembly, and to launch the construction of three drilling equipment plants.

The Ufa Motor Plant (ODK – Ufa Motor-Building Association today) that used to produce harvester engines, became the site for aircraft-building enterprises from Rybinsk, Moscow and Leningrad. The construction of the plant began ten years before the war, and only four years later it produced its first engines for agricultural vehicles. In 1940, the plant was expected to reach full capacity, but was instead transferred to the ministry responsible for aircraft-building in the Soviet Union.

In wartime the Ufa Motor Plant manufactured the Klimov-design M-13 and VK-105 aircraft engines, producing 50-60 units a day. Over the four years of the war the plant manufactured over 5,000 aircraft engines. Its engineers and workers produced engines for Pe-2 bombers and Yak-3, Yak-7 and Yak-9 fighter aircraft.

The aircraft-building equipment at the Ufa Motor Plant had to be installed during the coldest winter months of 1941 – 1942. But despite the severe cold the workers constructed 11 production shops, laid down 42 km of railways and built a depot and transport facilities. The strategically important construction project employed 6,600 people who were accommodated in the 127 newly erected buildings and barrack houses and at two camp sites.

The important role played by the Ufa Motor Plant in the war effort can hardly be overestimated: every third aircraft carried the engine it produced, and the Yak-9U running an Ufa motor was pronounced the fastest WWII aircraft fighter.