Workers of sheet-rolling workshops at metallurgical plants were called sheet metal rollers. They heated metal stocks in a special furnace, and then fed them into the arbor of the rolling mill and rolled them several times to get the desired thickness.

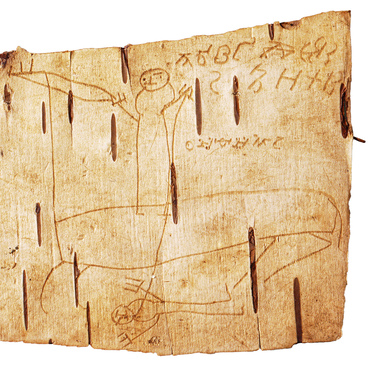

Working with hot metal required certain clothes and shoes. Rollers wore special shoes with a wooden base, which was lined with sheet iron on top and covered with asbestos paper, which is resistant to sparks. Inside, the shoes were lined with felt and tarpaulin.

A roller’s shoe was donated to the museum by members of the historical and household expedition who worked at the Goujon Plant in 1954 — in Soviet times it was called “Hammer and Sickle”.

The Goujon Plant — the largest metallurgical enterprise in Russia — was founded in 1883 by a Frenchman named Julius Goujon, who was born and raised in Moscow. His father, Pierre Goujon, had built a small nail factory behind the Butyrskaya Zastava, which his son later inherited. But in the 19th century, the industrial development in Russia was very rapid. Julius Goujon, taking into account the upcoming changes, decided that his business could grow only if he built a new, more modern metallurgical plant.

In 1883, Goujon began building a new factory on a vacant lot behind the Rogozhskaya Zastava. A year later, the rolling production was already underway; whereas in 1890 the first open-hearth furnace was installed and started operating. This technological novelty made it possible to obtain steel of the desired chemical composition and quality. In 1913, seven open hearth furnaces operated at the plant; they smelted more than 90 thousand tons of steel per year. The plant produced sheet metal, rolled metal products, beams for floors and bridges, rails, and shaped cast iron casting. The plant carried out defense orders during the First World War.

Over the years, the Goujon plant became famous not only as the largest steel producer in Russia, but also as one of the most “problematic” Moscow enterprises. Goujon did not introduce any social benefits for its workers, nor made concessions to striking employees, demonstratively arranged mass dismissals of dissatisfied ones. Even in hot workshops the working day lasted 12 hours, the injury rate was extremely high. However, the workers’ wages exceeded the average one in Moscow at that time.

In 1918, the plant was nationalized. In 1922, it was renamed Moscow Metallurgical Plant “Sickle and Hammer”, and in 2009 it was closed.

Working with hot metal required certain clothes and shoes. Rollers wore special shoes with a wooden base, which was lined with sheet iron on top and covered with asbestos paper, which is resistant to sparks. Inside, the shoes were lined with felt and tarpaulin.

A roller’s shoe was donated to the museum by members of the historical and household expedition who worked at the Goujon Plant in 1954 — in Soviet times it was called “Hammer and Sickle”.

The Goujon Plant — the largest metallurgical enterprise in Russia — was founded in 1883 by a Frenchman named Julius Goujon, who was born and raised in Moscow. His father, Pierre Goujon, had built a small nail factory behind the Butyrskaya Zastava, which his son later inherited. But in the 19th century, the industrial development in Russia was very rapid. Julius Goujon, taking into account the upcoming changes, decided that his business could grow only if he built a new, more modern metallurgical plant.

In 1883, Goujon began building a new factory on a vacant lot behind the Rogozhskaya Zastava. A year later, the rolling production was already underway; whereas in 1890 the first open-hearth furnace was installed and started operating. This technological novelty made it possible to obtain steel of the desired chemical composition and quality. In 1913, seven open hearth furnaces operated at the plant; they smelted more than 90 thousand tons of steel per year. The plant produced sheet metal, rolled metal products, beams for floors and bridges, rails, and shaped cast iron casting. The plant carried out defense orders during the First World War.

Over the years, the Goujon plant became famous not only as the largest steel producer in Russia, but also as one of the most “problematic” Moscow enterprises. Goujon did not introduce any social benefits for its workers, nor made concessions to striking employees, demonstratively arranged mass dismissals of dissatisfied ones. Even in hot workshops the working day lasted 12 hours, the injury rate was extremely high. However, the workers’ wages exceeded the average one in Moscow at that time.

In 1918, the plant was nationalized. In 1922, it was renamed Moscow Metallurgical Plant “Sickle and Hammer”, and in 2009 it was closed.