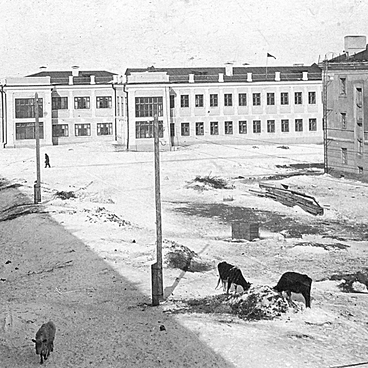

The meat processing plant was the first large industrial enterprise set in Orsk during the first five year plan. Construction started in November 1931. The decision surrounding its construction was confirmed in a resolution of the Central Committee of the All-Union Communist Party and the USSR’s Council of People’s Commissars in 1931, entitled ‘The development of the meat and canning industry.’ This resolution envisaged the creation of eight large meat processing plants across the country, including the one in Orsk. Its location was decided on the one hand by the fact that it would be in the center of the future Orsk-Khalilov industrial complex, and needed to supply meat to all the nearby factory workers. On the other hand, the meat processing plant was built close to its raw materials: including fourteen districts of the Kazakh SSR, five districts of Bashkiria and twelve regions of the eastern part of the central Volga region. The plant’s construction was based on technology acquired from the USA. Its construction was helped by a team of American specialists. The project was initially planned for completion in 1933. Then the enterprise decided to reduce the size of the project from a giant-sized to a medium-sized processing plant, which delayed the launch to 1934. As a result, the plant’s first products rolled off the production line in 1935, and the enterprise’s first stage was accepted by the Commission in 1938. The exhibition also includes a photograph of the completed refrigeration unit.

Despite the large scale of the plan, construction was largely carried out with manual labor. The technology used for manual excavation are clear to see: diggers dug small pits and porters used wheelbarrows to move the excavated soil to the conveyor belt. The conveyor belt took the soil away from the foundations.

At the same time, steam-driven excavators were being used on building sites. Similar methods were used to construct other large buildings in Orsk, including the locomotive factory, the thermal power plant and the oil refinery.

The meat processing plant’s builders were recruited from Orenburg and neighboring regions (the majority of them were illiterate peasants, who didn’t work in construction), as well as residents of a settlement for dispossessed peasants, situated next to the construction site.

Despite the large scale of the plan, construction was largely carried out with manual labor. The technology used for manual excavation are clear to see: diggers dug small pits and porters used wheelbarrows to move the excavated soil to the conveyor belt. The conveyor belt took the soil away from the foundations.

At the same time, steam-driven excavators were being used on building sites. Similar methods were used to construct other large buildings in Orsk, including the locomotive factory, the thermal power plant and the oil refinery.

The meat processing plant’s builders were recruited from Orenburg and neighboring regions (the majority of them were illiterate peasants, who didn’t work in construction), as well as residents of a settlement for dispossessed peasants, situated next to the construction site.