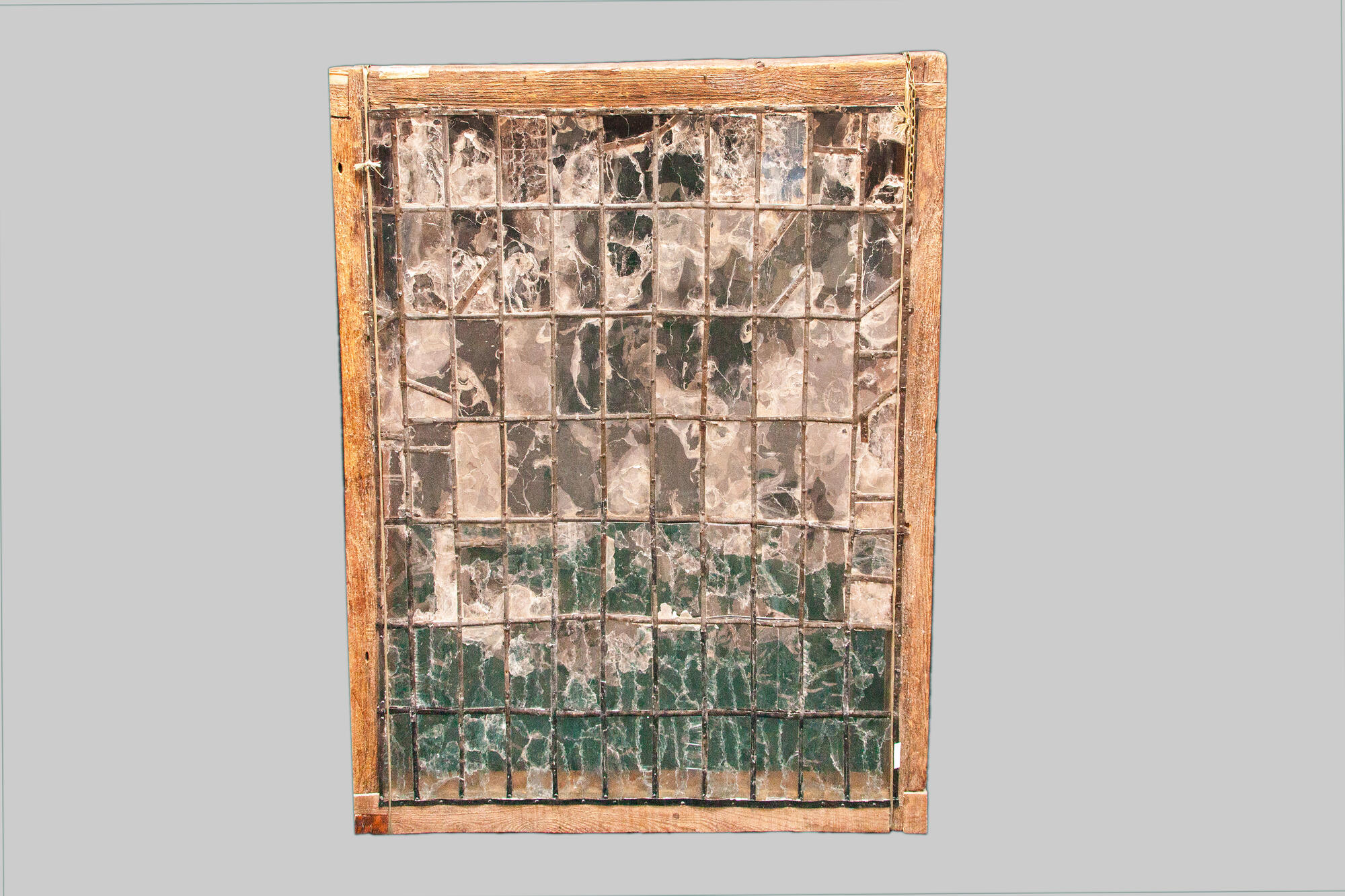

The first glass factory was built in Russia in 1635 near Moscow. Before that, mica plates were inserted into the windows. An example is a window casement in the form of a wooden frame with mica inserts, presented in the exposition of the Tobolsk Museum Reserve. In the 16th–17th centuries, mica covered window casements in the royal palaces, churches, merchant and boyar houses. It was used to decorate the refined doors of boxes, caskets, furnishings of churches, and icons.

In Ancient Rus mica was often called ‘Moscow glass’ and ‘crystal’. To create a single window casement, the craftsman had to connect small pieces of mica with metal plates that formed a straight or oblique grid, and insert them into the groove of the wooden frame. Mica plates could serve as a screen in lamps and lanterns to cover the source of open fire.

Russian mica was valued quite highly: the cost of goods, depending on the quality, could reach from 15 to 150 roubles per pood. Siberian voivodes tried to find local raw materials and establish supplies from the Urals. The main part of the natural mineral was used to supply the Siberian cities of Tobolsk, Tyumen, and Tara, which can be seen as examples of the rapid production of mica windows in the first Russian cities of Western Siberia.Mica found in the fields of the Urals was delivered to Moscow in large volumes and from there it went to the West and East. It was considered the best in the world, in European countries it has been called ‘muscovite’.

In the second half of the 17th century, there was a gradual expansion of the extraction of Siberian mica, but in the 18th century, craftsmen began to use glass sheets for manufacturing windows. It has replaced the mica windows. At first, mica disappeared from the homes of rich people, and later it could only be seen in the windows of peasant houses. In some regions of Russia, mica window casements were preserved until the early 20th century. Currently, mica window casements are especially valuable to the museum.

In Ancient Rus mica was often called ‘Moscow glass’ and ‘crystal’. To create a single window casement, the craftsman had to connect small pieces of mica with metal plates that formed a straight or oblique grid, and insert them into the groove of the wooden frame. Mica plates could serve as a screen in lamps and lanterns to cover the source of open fire.

Russian mica was valued quite highly: the cost of goods, depending on the quality, could reach from 15 to 150 roubles per pood. Siberian voivodes tried to find local raw materials and establish supplies from the Urals. The main part of the natural mineral was used to supply the Siberian cities of Tobolsk, Tyumen, and Tara, which can be seen as examples of the rapid production of mica windows in the first Russian cities of Western Siberia.Mica found in the fields of the Urals was delivered to Moscow in large volumes and from there it went to the West and East. It was considered the best in the world, in European countries it has been called ‘muscovite’.

In the second half of the 17th century, there was a gradual expansion of the extraction of Siberian mica, but in the 18th century, craftsmen began to use glass sheets for manufacturing windows. It has replaced the mica windows. At first, mica disappeared from the homes of rich people, and later it could only be seen in the windows of peasant houses. In some regions of Russia, mica window casements were preserved until the early 20th century. Currently, mica window casements are especially valuable to the museum.