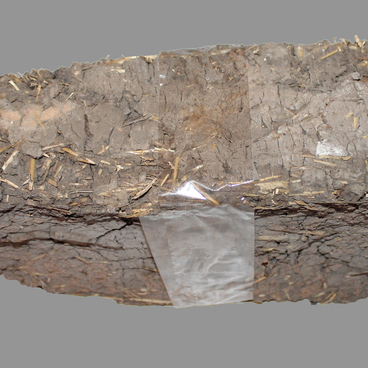

The material most commonly used in the construction of oil facilities in the IshimbAy region during the 1930s was wood. For this reason, local carpenters, joiners, and construction workers could often be seen armed with jointer planes like the one stored in the collection of the IshimbAy Museum of History and Local Lore.

The jointer plane is a hand-held carpentry tool designed for fine shaving, as well as for flattening large surfaces and jointing separate pieces. It is used once the wood has been treated with a jack plane and a hand plane. In its design, the tool looks like a longer type of a hand plane that has been fitted with a double blade.

The jointer plane is intended for achieving a high-quality surface finish when working long pieces: for example, when straightening the edges of boards before gluing them together. Smaller surfaces are usually worked with the shorter and narrower semi-jointer plane. The front of the jointer plane’s body has a lever cap that loosens the blade when hit with a wooden mallet. Additionally, the body of the jointer plane is fitted with a handle that sits behind the blade.

When a jointer plane is used on an initially uneven surface, the shavings come out as small pieces; however, with subsequent passes, they become continuous, indicating that the surface is getting smoother. The jointer is considerably longer than the other types of planes—the jack plane and the hand plane—and its blade is positioned at a 45-degree angle. Some jointer planes also come fitted with a chipbreaker, which is a component that breaks apart wood shavings and removes them from the work surface.

The jointer plane goes back centuries. Archaeologists date the oldest known tool of a similar type, a hand plane, to the 4th or 3rd century BC, and based on the other archaeological finds, at least some components used in wood planing had come into use even earlier. The design of the hand plane has remained unchanged; however, a wide variety of its types have since been designed, including the draw shave, the compass plane, the bead plane, the jointer plane, the finishing plane, the jack plane, the shoulder plane, the rebate plane, the router plane, and a lot more.

The jointer plane is a hand-held carpentry tool designed for fine shaving, as well as for flattening large surfaces and jointing separate pieces. It is used once the wood has been treated with a jack plane and a hand plane. In its design, the tool looks like a longer type of a hand plane that has been fitted with a double blade.

The jointer plane is intended for achieving a high-quality surface finish when working long pieces: for example, when straightening the edges of boards before gluing them together. Smaller surfaces are usually worked with the shorter and narrower semi-jointer plane. The front of the jointer plane’s body has a lever cap that loosens the blade when hit with a wooden mallet. Additionally, the body of the jointer plane is fitted with a handle that sits behind the blade.

When a jointer plane is used on an initially uneven surface, the shavings come out as small pieces; however, with subsequent passes, they become continuous, indicating that the surface is getting smoother. The jointer is considerably longer than the other types of planes—the jack plane and the hand plane—and its blade is positioned at a 45-degree angle. Some jointer planes also come fitted with a chipbreaker, which is a component that breaks apart wood shavings and removes them from the work surface.

The jointer plane goes back centuries. Archaeologists date the oldest known tool of a similar type, a hand plane, to the 4th or 3rd century BC, and based on the other archaeological finds, at least some components used in wood planing had come into use even earlier. The design of the hand plane has remained unchanged; however, a wide variety of its types have since been designed, including the draw shave, the compass plane, the bead plane, the jointer plane, the finishing plane, the jack plane, the shoulder plane, the rebate plane, the router plane, and a lot more.