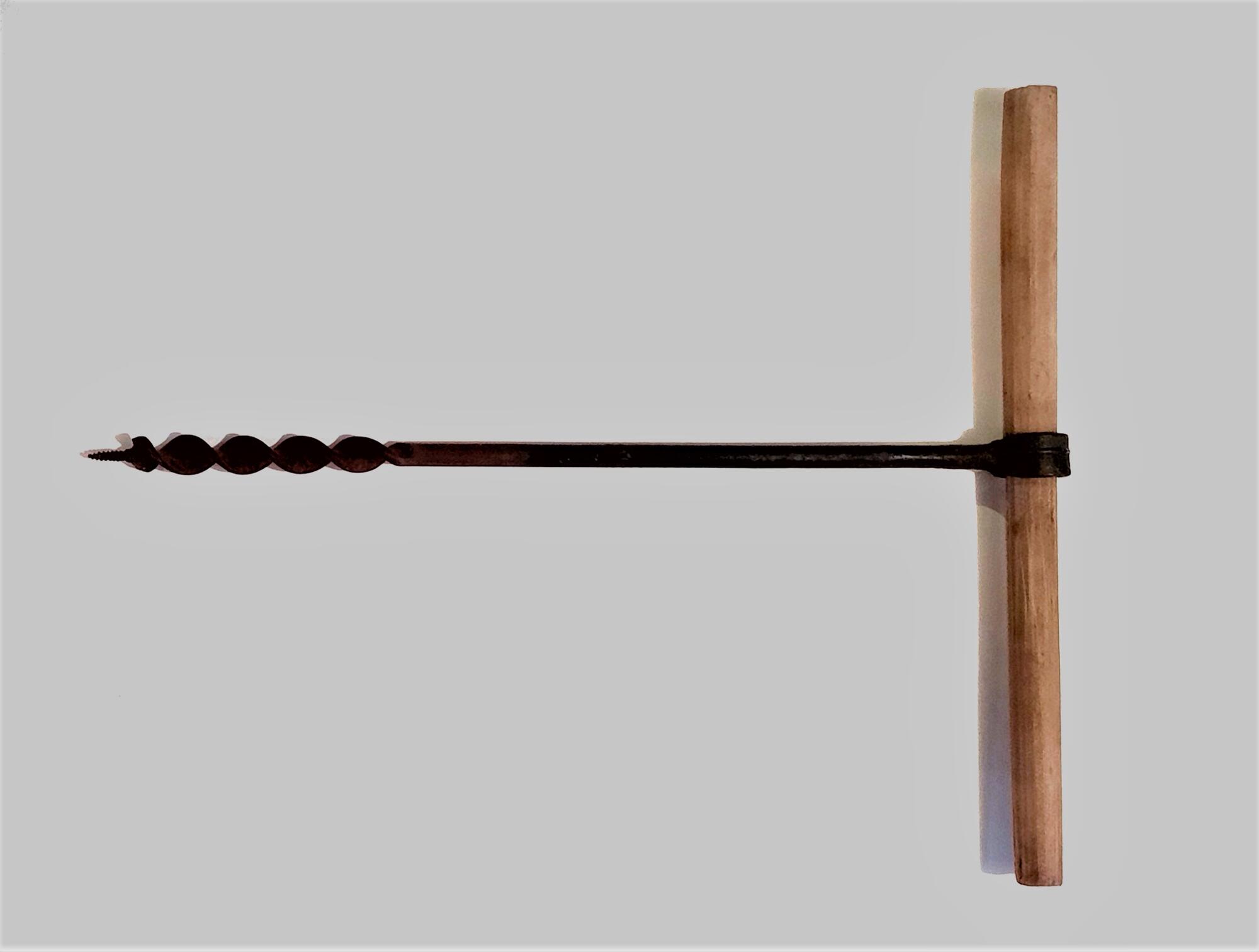

A hand drill, or gimlet, is a tool designed for making holes in wood and other soft materials. The collection of the Ishimbay Museum of History and Local Lore contains a steel drill painted in black and fitted with a wooden handle. Since it is a gimlet, the tool’s boring bit begins in a cylindrical shape and turns into a screw thread near the end. The tip of the tool has a screw-shaped point for a better grip on wood. Carpenters who worked at Ishimbay’s construction sites used these tools for a wide variety of purposes.

The presence of helical flutes, like the ones seen on the shaft of the gimlet displayed in the museum, facilitates the removal of swarf, especially when deep drilling. Additionally, the drill’s helical body enables to regrind any point along the entire length of the screw into the new cutting bit. The cutting bit itself consists of the center point, the cutting edge (also known as the lip), and the spurs. The lip and spur bits are used for drilling across the grain. When drilling, the spurs cut the wood fibers in front of the cutting edge, making a circular cut.

Additionally, gimlets are sometimes fitted with auger bits, which are distinguished by their spiral cutting edges. Such bits are used for drilling butt ends along the grain or drilling at an angle. Another type of gimlets comes fitted with twist drill bits that are ground in a conical shape with variations depending on the size of the drill’s point angle (the angle between the cutting edges). Such tools are used both for drilling along and across the grain, as well as for drilling at an angle.

The purpose of the center point is to guide the bit in the correct direction when drilling. This center can have a pyramidal or helical shape. The length of the center point can range from one-fifth to half of the drill diameter. The helical shape of the center point helps drive the drill into the wood at a feed rate equal to a single screw pitch per revolution.

Gimlets require timely and proper maintenance in order for them to last longer. Here, key importance is attached to sharpening, which should be done with a fine-grained grinding wheel or by hand using a file. To sharpen a drill, the file must have a higher hardness than that of the cutting edges of the bit.

The presence of helical flutes, like the ones seen on the shaft of the gimlet displayed in the museum, facilitates the removal of swarf, especially when deep drilling. Additionally, the drill’s helical body enables to regrind any point along the entire length of the screw into the new cutting bit. The cutting bit itself consists of the center point, the cutting edge (also known as the lip), and the spurs. The lip and spur bits are used for drilling across the grain. When drilling, the spurs cut the wood fibers in front of the cutting edge, making a circular cut.

Additionally, gimlets are sometimes fitted with auger bits, which are distinguished by their spiral cutting edges. Such bits are used for drilling butt ends along the grain or drilling at an angle. Another type of gimlets comes fitted with twist drill bits that are ground in a conical shape with variations depending on the size of the drill’s point angle (the angle between the cutting edges). Such tools are used both for drilling along and across the grain, as well as for drilling at an angle.

The purpose of the center point is to guide the bit in the correct direction when drilling. This center can have a pyramidal or helical shape. The length of the center point can range from one-fifth to half of the drill diameter. The helical shape of the center point helps drive the drill into the wood at a feed rate equal to a single screw pitch per revolution.

Gimlets require timely and proper maintenance in order for them to last longer. Here, key importance is attached to sharpening, which should be done with a fine-grained grinding wheel or by hand using a file. To sharpen a drill, the file must have a higher hardness than that of the cutting edges of the bit.